One evening a couple of months ago, when i was looking at metalnecks.com, which links to a lot of aluminium guitars, it struck me that the majority of guitars have wooden bodies with aluminium necks or aluminium bodies with wooden necks. There were comparably few one-piece aluminium guitars. And no aluminium "neck-through"-necks with attached wooden "wings" at all. That puzzled me a bit, because it seems that among luthiers using wood, the neck-through design is widely considered the best overall solution.

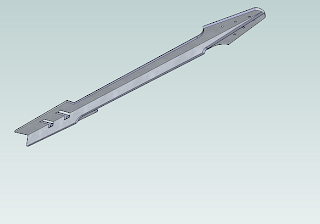

I tried to imagine how an aluminium neck-through-neck would look. It might be made from a single long slab of aluminium. That would be very heavy, so you'd probably route out some of the material along the neck like the Kramer aluminium neck. Then you'd get something looking a lot like an aluminium T-beam. You know, these metal beams used for load bearing parts of houses among other things.

Why not use a stock T-beam? That'd be way cheaper than having the neck made from a big slab of aluminium on a CAM router. I think it can be done in the following steps.

You start out with at T-beam, which will act as sort of a spine in the guitar. A top flange of 100mm, a bottom flange of 60mm and 5 mm flange thickness (that will be approx 4, 2,4 and 0,2 inches) will be suitable. They are available, but - as it should turn out later - not exactly readily available.

The T-bar is cut to shape (Pickup holes, neck and head). Due to the width of the pickup holes, the T-bar has to be quite wide in order to keep its structural strength. With a narrower T-bar, the pickup holes would completely intersect the top flange, weakening the T-bar considerably.

Having modified the T-bar, you screw or glue on wings (like on a wooden neck-through guitar), fingerboard and some pieces of wood to give the neck its desired shape. Plus, of course, route out cavities for electronics, sand the body, mount bridge, nut, etc, etc.

This way, you get a guitar with a lot of structural strength from the T-beam. You have great freedom of choice of wood and shapes of the body. And best of all: It should be possible to do it with ordinary do-it-yourself tools (hand held router, metal saw, sand paper, electric drill, belt sander, etc.).

I think it will work. I think it will look amazing. I am not sure how it will sound, but I am going to build myself one. Then we shall see. Or rather hear.

I'll post updates on this blog. I've already done some designing and planning plus a couple of purchases. This will be described in separate posts in the near future, and I expect that when I get around to the actual construction of the thing, my posting will have caught up, and I'll be posting in more or less real-time.

34 comments:

Great Blog and Great designs. It good to see innovative guitar designers! Keep on blogging and designing.

Thanks! I will.

Interesting concept. I think the only problem you will have is adjusting the forward or backward bow of the neck because there is no truss rod. A guitar neck needs some forward bow to avoid fret buzz, this design would be perfectly flat.

You might have a point. I expect the neck to curve very slightly when the strings are on. If by then I can't get proper action by adjusting the bridge (and screws on the nut which I'm planning), then I'll probably have to install a truss rod on each side of the bottom flange.

Still, I'll try without truss rod and see how it works.

With such a radical concept as an aluminum neck, why not use the conductivity of the alumium to become the ground return in a low impedance, individual string pickup. It works like this. Connect the strings to a metal nut that is electrically connected to the aluminum neck. The neck acts as the common ground return along with the six hot connections behind the bridge. Insulated intonnation inserts need to be used to prevent the strings from shorting out.

Each string acts like the vibrating element of a ribbon microphone. A voltage is induced in each individual string when a magnet is placed near the strings. The string impedance is in the range of a fraction of an ohm to about 1 ohm. Use six 4 ohm to 10K or 20K or higher miniature transformers, one for each string. Wire each transformer low Z side to the heel of the neck as the common ground connection point and the other end to the string behind the bridge. The string acts like a one turn loop which actually has a voltage induced on it when vibrating in a magnetic field. The transformer turns ratio boosts the string output level to something that the amp can more easily use.

You can combine strings or have independent outputs to drive a midi converter or even have six separate outputs to send the guitar signal to a six-channel microphone mixer with independent volume, pan and EQ control of each string.

This is just some food for thought to extend the use of an aluminum neck into a very high fidelity guitar.

Enjoy

bbsailor

Fascinating idea!

I can see that my design lends itself well to the principle, but I assume it could be done by using the truss rod of a traditional electric guitar plus a length of cable under the pickguard, connecting to the bridge. Meaning that others also have the option of experimenting.

I know too little of electronics to acknowledge that it'd work. Has it ever been done? (if it hasn't, it's fun and interesting because it's new. If it has, on the other hand, it's more reassuring since you know it can function).

Alexander

Everything you need to know to try this idea is in the following two U.S. Patents by Martin Clevenger.

Patent 4408513 in 1863

Patent 4499809 in 1985

This patent will produce a pickup that has a very wide and rather flat frequency that has sort of an acoustic quality as more upper harmonics are produced compared to traditional guitar pickups with 5,000 to 10,000 turns of AWG42 wire.

bbsailor

OOPS

Patent 4408573 was issued in 1983.

bbsailor

Double OOPSE

My eyes are bad trying to copy off old notes. Sorry.

The real Clevenger Patent number is 4408513 in 1983.

bbsailor

I dont think there will be much neckbow if any. I've put together two longscale 10 string basses with alu-necks quite similar to this (but not as cleaver) with string gauges from .100, and i didn't notice any neckbow actually.

What i don't get is what you will do for frets? (mine was fretless)

Gary,

I'm glad to hear that it worked for you without further reinforcements of the neck. It sounds promising for my project.

I plan to use traditional frets in a rosewood fretboard glued on top of the t-beam, so that part of the guitar is fairly ordinary.

I love your enthusiasm but coming from a guitar lutherer its a bad idea. Here is why it is a waste of your time to make this.

The neck is a bow. It's supposed to bow. A perfectly strait neck would rattle or not play notes. The best necks, and most expensive produced by places like Guitar Factory in orlando, use a neck-though design. that way both ends of the string from head to bridge are on the same piece of wood, with the help of a truss rod, this happens to produce the most notes without rattle on a fretboard. It needs to be flexible.

Your idea could work if you make it thin enough to bow perfectly for a specific string gauge. But metal is effected greatly by temperature, body heat room temperature, indoors and outdoors would noticeably change its playability in different conditions. Even sunlight would effect it. Metal is used for temperature gauges because it expands so much in heat.

you could insulate it, hm.. in wood perhaps because wood is a fairly reasonable insulator and it happens to resonate well.

And you could make this metal neck out of tungsten because it is both hard and reacts mildly to normal temperature changes. Because it is harder you'd have to make it much smaller.

Guess what? someone beat you to the punchline over 100 years ago, it's called a Truss Rod.

But sadly, the truss rod got shortened to accommodate the shorter bolt-on necks.

If you made a truss rod extend from tuning pegs to the bridge then you'd be on to something! But good custom shops already do that. I already do that. :/

Sry man. glad you realized normal truss rods need change. Look up neck-through guitar designs. They are nearly perfect already, and they aren't all that hard to make.

Hi Jon

Thanks for the advice. As you can see, more than a year has passed since this first post. And nothing much has happened, to some extent due to the issues, which you mention.

I do expect the T-beam to bow a bit under the tension of the strings. If it’s not enough, I’ll have to use a weaker T-beam. You’re right about the truss rod, and I’ll probably have to use one to get the correct bow.

I did give the high termal expansion of aluminium some consideration. I've heard about problems with aluminium guitars expanding in the heat and becoming unplayable.

I don’t think insulating it will work. It couldn’t keep the guitar at the desired temperature for hours (which is what you’d need). I even considered building it to be perfect at a certain, relatively high, temperature (say 40 degrees Celsius), and keeping the guitar at that by electric heating elements and thermostats.

Tungsten sounds nice, but isn’t it brittle? …and expensive?

I’d have to make my own truss rod running the whole length of the guitar. It seems pretty straightforward. At least compared to the other tasks, I have. But on a traditional neck-through guitar, I am not sure it is necessary having the truss rod go all the way to the bridge. Wouldn’t the body provide more than enough stiffness in most cases?

/Alex

If you choose the right alloy with correct design and dimensions, the neck should be pretty stiff.

Tungsten is a joke, elemental tungsten is absolutely not viable, only someone who never opened a book concerning metal alloys could say this.So childish

Truss rods are one of the most STUPID inventions in regard to the electric guitar world: if you change often string gauges, use extensively whammy bar and experiment detuning, a truss rod neck will simply give up with time.

Wood is simply not made to be put put under such a stress in two different directions (truss rod in one dir. strings pulling on the other).

Carbon rods were an improvement, but I think all metal necks (or T-beam designs as well) could be an even better alternative.

Don't forget Kramer came up with T-beam aluminum necks, and a french luthier came up with the idea of an aluminum alloy plate in a neck through design.

Forged aluminum would be even stiffer (as Kramer did use it).

Final word: if a neck is stiff enough to not be bent AT ALL under the heaviest gauge strings, then there is NO NEED to have "bow action" or any adjustable back bow device as a truss rod. Anyone who isn't ok with this should just go to a library and QUICKLY borrow mechanics books from the library and learn, FAST. I took the the time to do it, but some just think they're too smart to learn anything.

Of course, such a neck would be only hypothetical as there is ALWAYS a bit of curving, but with the right metal or composite (carbon fibers, ceramic fibers etc)

design, this neck would be under only a MINUTE degree of curvature, so small that it wouldn't affect the string action or the buzzing at all ( 100th or even 1000th of millimeter)

yeehaw

ps: who's the half asleep guy who claims "a neck needs to be like a bow, elastic"? For tone AND stability, the stiffer the better, and it's true even in classical lutherie. A extremely stiff neck lacking a truss rod will just be a nightmare for electric guitar shop repairsmen: nothing to repair!!! no adjustment!!

Alex,

That is a fantastic idea.

I would like to build myself one also. But in my version - i will make it fretless, with the actual T-Beam being the fingerboard itself. I will also just have a bridge pickup only, and have the fingerboard go up all the way to the bridge pickup (if there were frets, it will be 40+ frets). So you could play very high.

I like your idea of screwing the T-Beam to the body with screws, rather than glueing things on. I think your idea is fantastic, and thank you for the inspiration.

I was going to create a 1 piece aluminum neck through myself, but this seems easier to do, cheaper and lighter.

We should keep in touch. Keep posting upon your progress. I'm subscribing to your blog.

Thanks,

Alexei

Hi Alexei

Glad you like it. I'm building a bass with the design you describe - fretless on the bare aluminium (see my later posts). Did you intend to build a fretless (tenor) guitar?

There is one advantage to making your own neck. I have only found T-beams of AlMgSi0,5 (a.k.a. 6063 Aluminium), which is a rather soft alloy - not good for cutting and drilling. If you made your own neck/stick, you could choose one of the harder alloys for strength and perhaps vibration characteristics. If you had access to the proper machinery (I haven't), you could mill your own custom T-beam.

But yes, they _are_ cheap and sufficiently strong.

Good luck on your build. I look forward to seeing the progress and results... it's always interesting to see how somebody else will approach the same basic concept.

/Alex

errg

i am a high end guitar maker 180+@£700-1100 each ive always made the designs different from anything else but always out of wood and ive always been interested in metal or composite material guitars but ive always instantly dismissed the idea as an unviable one 4 times already but some of the comment be it theoretical or real make it seem a bit more possible than it was. thanks to all, and now im gonna go in my workshop as soon as i finish work and test it out. btw sorry for the first post i wanted to see if you could post before setting up an account

Hi Ben

Good luck on the build. I'm glad that the comments have thrown a positive light on your project.

Is there a chance to see the instrument, you're about to build (sketches, in-progress pictures, etc.)?

/Alex

hi guys,

right now i am about to design a necktru aluminium guitar...

one thing you have to consider is that youll not be able to get an alu. neck to bow... but:

my ideas to make it bow are:

a) make "steps" inbetween the fret wires... => so that the 12th fred is the lowest and it goes up step by step to the first and the last... you could have the optimal "bow" with this.. and no further adjusting would be needed...

but you would have to go with your own fred wires...

b) you all know the indicators on the 3rd 5th 7th etc fred...right?

(birds on prs guitars etc.)

so... what could be done is that you make vertikal "cuts" as your indicators => that would weaken the aluminium neck ... the cut should be the deepest on the 12th fred ... with a little experimenting one could find the ideal dimensions of theses "cuts"... so that the neck would bow...

yay...

sorry for my englisch...

what do you guys think?

It sounds like a good idea to make some sort of relief or bow in the neck so that it isn't completely straight.

The steps sound doable, but wouldn't each step be so small that it wouldn't matter if you just made a big soft curve on the neck instead? Plus, then you'd be able to use ordinary fretwire.

Btw, even if you made steps, you could use ordinary fretwire. If you make the cut for the fret around 2 mm from the edge of each step instead of cutting on the exact ends of the steps, it should work.

I think I get your point on cutting the neck to allow it to bow, but it sounds like it will be hard to get it correct. If you have access to a metal router, the first idea with the steps sounds better to me.

/Alex

hi , very very interesting...different from all the woody guitars for once...all th ebest...

i am infact ding a zemaitis style guitar nw, but am still figuring out the right aluminium grade to use....

Bernard,

I've tried to find out which aluminium alloy is best with regards to sound but haven't found out anything. But the harder alloys (e.g. AlZnMgCu aka 7075 aluminium) are stronger and better suited for cutting, filing, milling, etc than the softer alloys such as AlMgSi0,5, aka 6063.

Good luck on your project.

thanks!!! imight even be considering titanium nw... :) any comments on it?

thanks!!! imight even be considering titanium nw... :) any comments on it?

Titanium is expensive, hard on the tools and I'm not sure how its sound properties are. It's strong and beautiful, but I'd stay away from it and stick to aluminium.

I built an aluminum body guitar out of 14 gauge aluminum 6061 just some scraps laying around

I used 3 inch channel at bridge and 1/8 inch inside the guitar body for support,at the point where neck bolts on I used 3/4 inch plate (size of the neck heel)

and used mig and tig welding. I bought a used neck and hot rail pickup . The guitar is sweet for metal and clean guitar work both it is the best guitar in my collection. The cost was aprox. $200 and about 20 hours of work,can be seen at, www.myspace.com/stgeorgeandfriends

That's a good looking guitar you've made. It looks solid with the massive aluminium bars making out the neck pocket and body center. Impressive that you did that in 20 hours.

/Alex

Very late on the scene post

Good work to all

I dont think a guitar has to have upbow Jon. If it is deemed necessary then the fingerboard could be tapered longitudinally(viewed laterally) from nut to saddle to stop string buzz/rattle and still carry radius in profile. I reckon what we have here now is the truss rod full length Jon just like you say it should and it can now do its rightful job Kamusur

I have just found your Blog (I am glad to say).

I have been thinking about making an all Aluminium Skeletal Guitar for my son.

I love your idea to use a T beam and have noted the comments abot Bow.

Since a T section of the required dimensions is so difficult have you thought about making the section from two pieces of flat stock. That way you could profile the lower flange for the bow and the weld them together forcing the upper flange to adopt the profile of the lower. Voila - an aluminium through neck with bow.

Hi Peter

Are you thinking of a fretboard wide top bar on top and a narrower bar on the bottom of the first one?

I think it's a very good idea. First of all, you have the option of using stronger and more machinable alloys with two bars. The T-beams only come in a very soft alloy, but with rectangular cross section bars, you have more choice.

I've been thinking of a neck with an adjustable curve this way (sort of a built-in truss rod). If you bolt the bars together at the bridge end, you can have adjustable tension at the headstock end by having a threaded hole in the end of the bottom bar and a bracket holding a screw on the top bar. Tightening or loosening the screw would change the curve of the neck.

A bit hard to explain without a sketch, but I hope you get the point :-)

/Alex

I've made about a dozen stringed instruments and about half have used aluminium as the main structure in the neck. The aluminium I use is soft, so there is a significant amount of bowing. The stiffest yet used a wooden chair leg cut in two with 10mm aluminum sections screwed into the top with the fret board expoxyed to 10mm sections. No detectable bowing with 6 strings.

This is such a brilliant and innovative approach to guitar design! The fusion of an aluminum T-beam with wooden wings is a fascinating concept, and your detailed thought process behind it makes for an inspiring read. It’s exciting to see someone push the boundaries of traditional luthiery and explore new possibilities in structure and sound. Can’t wait to see how this project evolves and hear the final result!

If you're looking for high-quality tonewoods to complement your aluminum construction, be sure to check out Exotic Wood Zone—they offer a fantastic selection of exotic and premium woods perfect for unique guitar builds like this!

Post a Comment